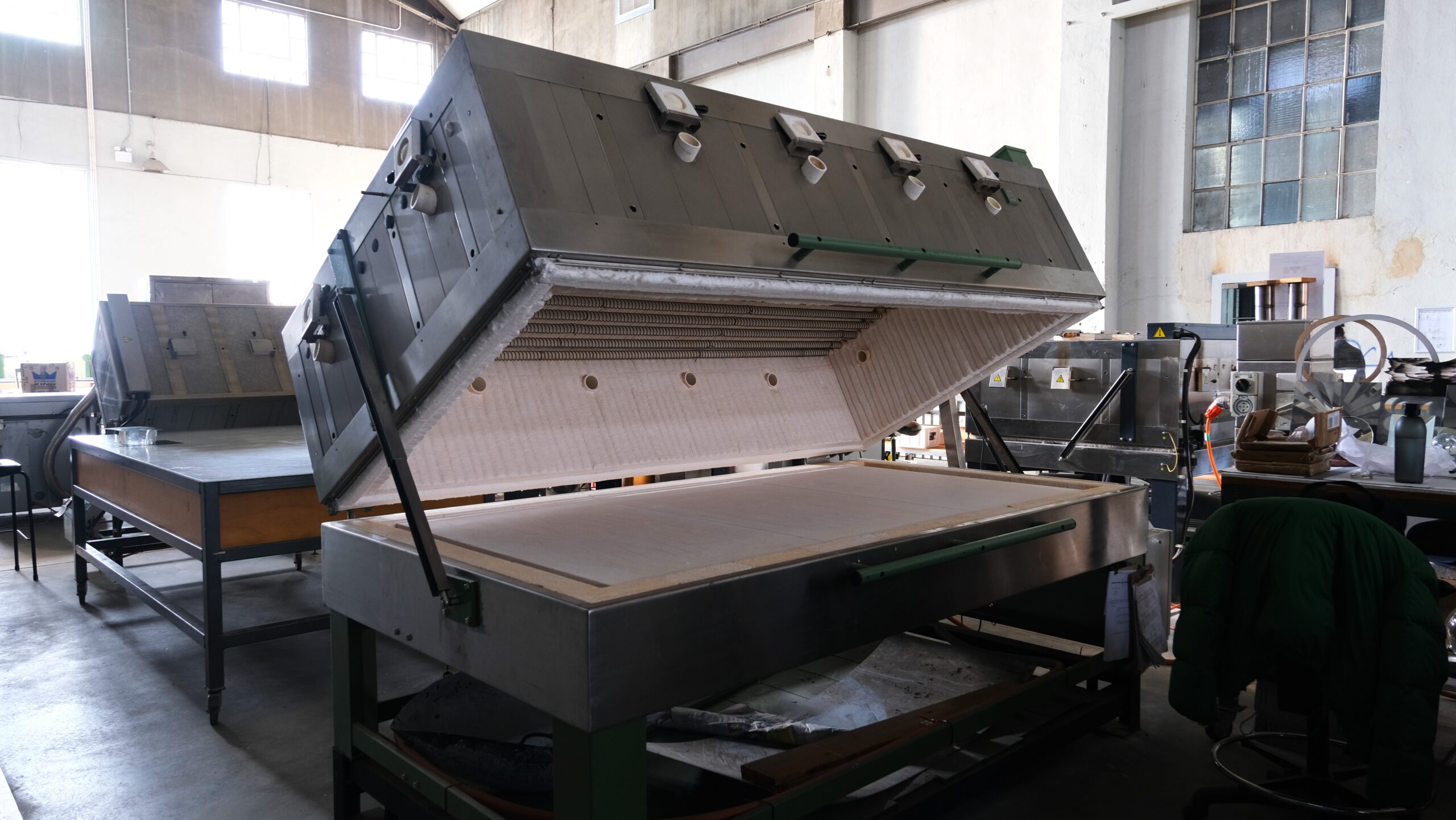

Kilns & Fusing

Kiln forming is the process of shaping and manipulating glass with heat and gravity in a kiln. This technique encompasses various processes such as fusing, slumping, and casting. Kiln forming allows artists to create a wide range of glass objects, including bowls, plates, sculptures, and decorative pieces. It offers the ability to experiment with different colours, textures, and layering techniques, resulting in unique and visually stunning glass artworks.

To enquire about hiring our facilities,

please contact our Artistic Programs Coordinator.

Click here for all Kiln & Fusing Equipment

Canberra Glassworks has with the following Kiln and Fusing Equipment available in the Engine Room & Project Space:

Woodrow Car Bed Kiln

Interior dimensions: 183cm d x 80cm h x 120cm w

2 x Small Woodrows

Top loader with air shock lift assist. Interior dimensions: 50cm h x 50cm d x 50cm w

Large Woodrow

Top loader coffin kiln with air shock lift assist. Interior dimensions: 60cm h x 60cm d x 140cm w

2 x Small BVD Peces

Clamshell kiln with air shock lift assist. Interior dimensions: 40cm h x 61cm d x 102cm w

2 x Large BVD Peces

Clamshell kilns with air shock lift assist. Interior dimensions: 125cm w x 104cm d x 41cm h

Extra Large BVD

Clamshell kiln with air shock lift assist. Interior dimensions: 35cm h x 105cm d x 210cm

2 x Medium Nabertherm (N440)

Tall front loader with right sidehinged door. Interior dimensions: 100cm h x 81cm d x 60cm w

7 x Paragons

Front loaders with right side-hinged door. Interior dimensions: 38cm h x 58cm d x 61cm w

2 x Small Nabertherms

Top loader with air shock lift assist. Interior dimensions: 38cm d x 40cm h x 43cm w

Other

- Hydraulic platform trolleys with 350kg – 500kg capacity

- Overhead gantry for maneuvering large heavy materials, moulds and objects

- Hepa Filter vacuum

- Sheet glass cutting table equipped with a strip cutter

- Small array of bricks and dams

- Portable thermacouples

- Historical log of past firings

- Dedicated extraction system for each kiln

- Large flat tables for laying and setting up work

- Large light table

- Polarising lenses

- A range of kiln controllers (EMC, Stafford, Nabertherm, Bentrup, 405/30, Bentrup 707)

- Diamond saw, specific for cutting kiln shelf

In addition to the necessary equipment, Canberra Glassworks offers a well-ventilated workspace designed to ensure the safety and comfort of artists. The studio is equipped with extraction systems to remove any harmful fumes generated during the glass blowing process.

Experienced technicians are also available to provide induction and support to artists utilising the facilities.